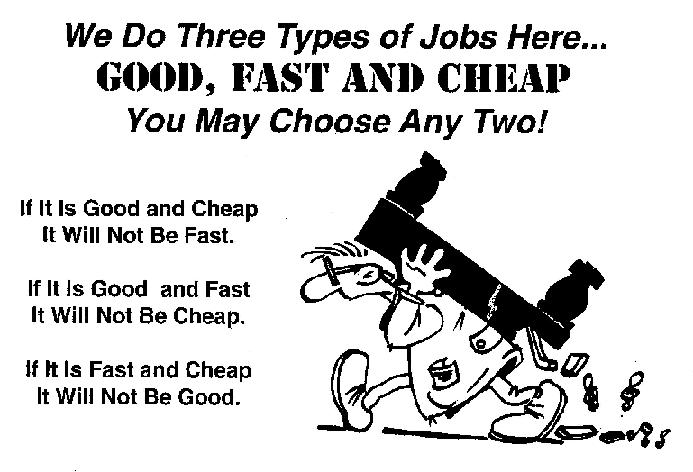

All joking aside, Twin Lakes Avionics strives to provide top-quality maintenance at competitive prices.

Installation – $130.00 hr

Bench repairs – $120.00 hr

Engineering – $175.00 hr

Experimental aircraft – variable, call for specifics.

Travel time – $130..00 hr + expenses (plane tickets etc…)

lodging – based on US government Per Diem rates

Saturday – standard time and a half

Sunday/Holiday – double time

91.411 & 91.413 (commonly referred to as VFR & IFR certifications) More Info

VFR – $100 Transponder only

VFR – $200.00 1 Transponder and altitude reporting check (no altimeter cert)

IFR – $300.00 1 transponder with mode A & C, 1 encoder, 1 altimeter

IFR – $375.00 1 transponder with mode A & C & S, 1 encoder, 1 altimeter

IFR – $400.00 PFD – 1 transponder with mode A & C & S, 1 encoder, 2 altimeters

Pressurized aircraft – add $50 to the above

We believe if you shop around and check apples to apples, you will find there is not a better price for the same work. You may find someone who is willing to cut corners to have the cheapest price, however, you will spend more fixing those cut corners in the future.

We will match any price on equipment, after all a Garmin GNS 430W is the same unit whether you buy it here or at Joe’s Shade Tree Air-motive. But should you sacrifice the quality of how it’s installed? Ask yourself: what corners have been cut to “slap it in the panel and make it work”. . .

The credit card companies have the catch phrase “What’s In your wallet”, I say “What’s your life worth”? Is 7000 ft AGL the time to find out your radio really did need that back strap support to keep it from getting in the controls?

Check out the rest of our site and see how much equipment and supplies we have here at Twin Lakes Avionics, also check out the qualifications of our staff and when you shop around you should be asking at least the following:

- Are they FAA certified A&P mechanics? Do you really want a non A&P ripping your aircraft apart, especially up in the panel where the controls are?

- Do they hold FAA Inspection Authorization? An IA is REQUIRED if you are going to fabricate support shelves,

bracketry, and instrument panels. - Do they hold an FAA Repairman’s certificate?

- Do they know how to do board level repairs? This is important to understand even during installation.

- Do they have factory training?

- Do they have a pilots license? Instrument rating?

- Do they have all the necessary manuals?

- Do they have the required test equipment to check it out and diagnose problems? For example Mode S transponders (Garmin GTX 330) require advanced test equipment not found at many avionics shops.

- Do they have sufficient MS and AN hardware on hand or are they going to “make due” with what they have?

- Are they going to label all wiring with a wire stamping machine, or do they use tape on the end until they connect it? Many new installation manuals reqire labeling every few inches on the wire, how difficult will it be to troubleshoot un-marked wires later on?

- If your having custom work done – do they have CNC capability? How about lathe or milling machine? The basic sheer and break? Or are they

going to hack it out with a pair of tin snips and a file then bend it with a hammer on the corner of a table? - Do they have Etch and Alodine submersion capability to to comply with methods and properties defined in Mil-C-5541-F & QPL-81706 for corrosion protection. or are they going to spray it down with a squirt bottle?

- Can they provide Screen printing if your needs require it?

- Do they know how to comply with DO-160E EMI, HIRF, and Lightning certification requirements? Equipment now available in smaller aircraft with High Speed Data Busses and the like require special attention to shielding and bonding that older legacy equipment did not require.

We encourage you to visit several shops and see where you’ll be spending 5, 10, or 30 thousand on something that keeps you alive at 8,000 ft AGL.

Twin Lakes Avionics has an assortment of working display units you can put your hands on and turn the knobs on the actual units so you can get a real feel of what you will be getting. There really is nothing like punching a flight plan in an actual working unit.

Want to see what actual weather looks like on a Garmin 696 or G600 — we have it on display! Want to see how an Aspen EFD 1000P looks up close and personal — we have it on display!! Want to see how well a CNC can cut your new panel or how much better silk screening looks – we have it on display !!!